Cement is a vital component of Singapore’s growth, and we are proud to be a part of it.

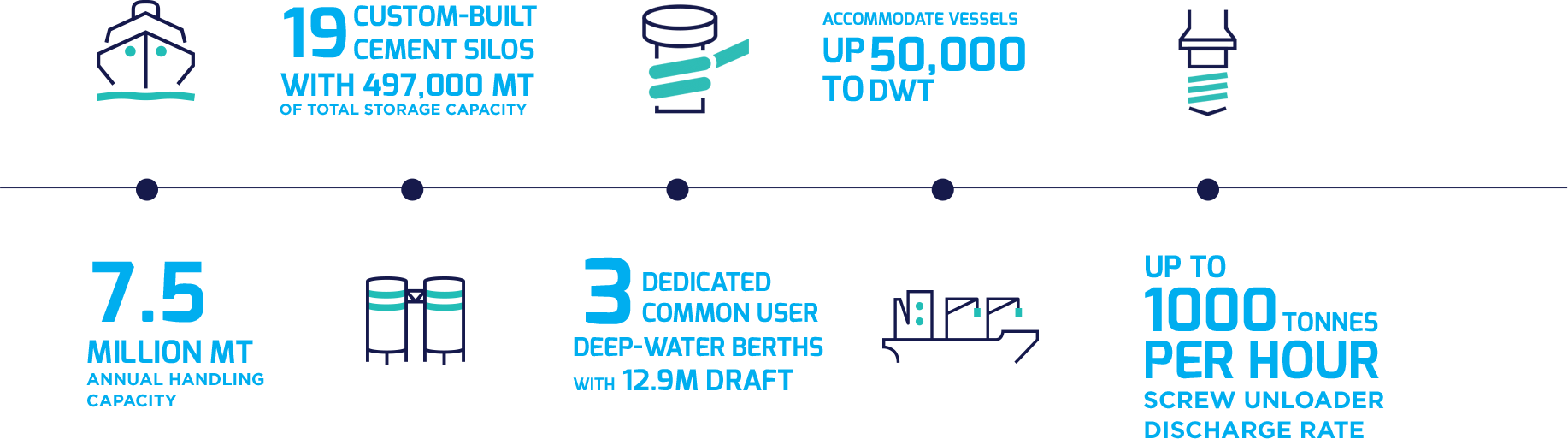

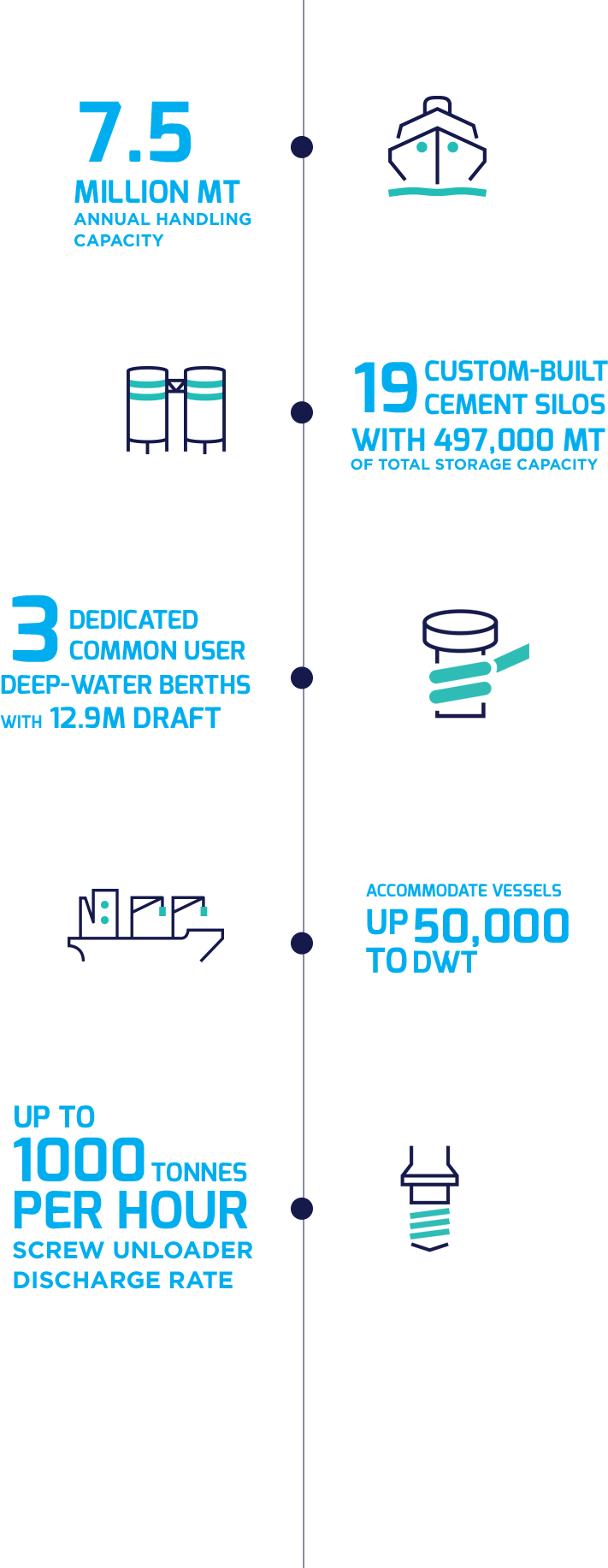

Jurong Port operates the world’s largest common user cement terminal, handling more than 90% of Singapore’s bulk cement imports and driving the local construction industry. Sited on a compact 5.3ha plot, the terminal have an annual handling capacity of over 7.5 million MT and come fitted out with cutting edge infrastructure and equipment to ensure a safe, efficient and environmentally-friendly discharge of cement.

SEAMLESS & EFFICIENT CARGO HANDLING

Cement Terminals 1 and 2 have a total of 3 dedicated deep-water berths and are equipped with 5 screw unloaders. The drafts are up to 12.9m and can accommodate vessels of up to 50,000 DWT.

Our screw unloaders can discharge efficiently at a rate of up to 1,000 tonnes per hour. This can be sped up further through dual-unloading operations, using two screw unloaders on a vessel simultaneously. Faster operations translate into quicker turnaround time for vessel discharging, leading to lower costs for cement consignees.

Jurong Port also proactively engages cement consignees for ideas to streamline the discharging operations and improve the prospects of a berth on arrival.

ADVANCED CEMENT HANDLING SYSTEM

Jurong Port’s cement terminal is equipped with an enclosed air-slide conveyor system that combines air pressure and gravity, allowing cement to flow easily into the storage silos. Our conveyor system is airtight, sound-insulated and environmentally-friendly.

TECHNOLOGY & INNOVATION

As a port, we are constantly innovating and looking for better solutions.

A feasibility study was conducted to determine the viability of automated unloading operations. Trials were carried out using weather- and dust-proof cameras mounted on unloaders that provided remote visibility on mobile devices, enabling cement unloader operators to work in safe, secure environments.

Jurong Port also embarks on other initiatives to semi-automate the cement discharging process with the use of lasers to guide unloaders, which improves discharging productivity.

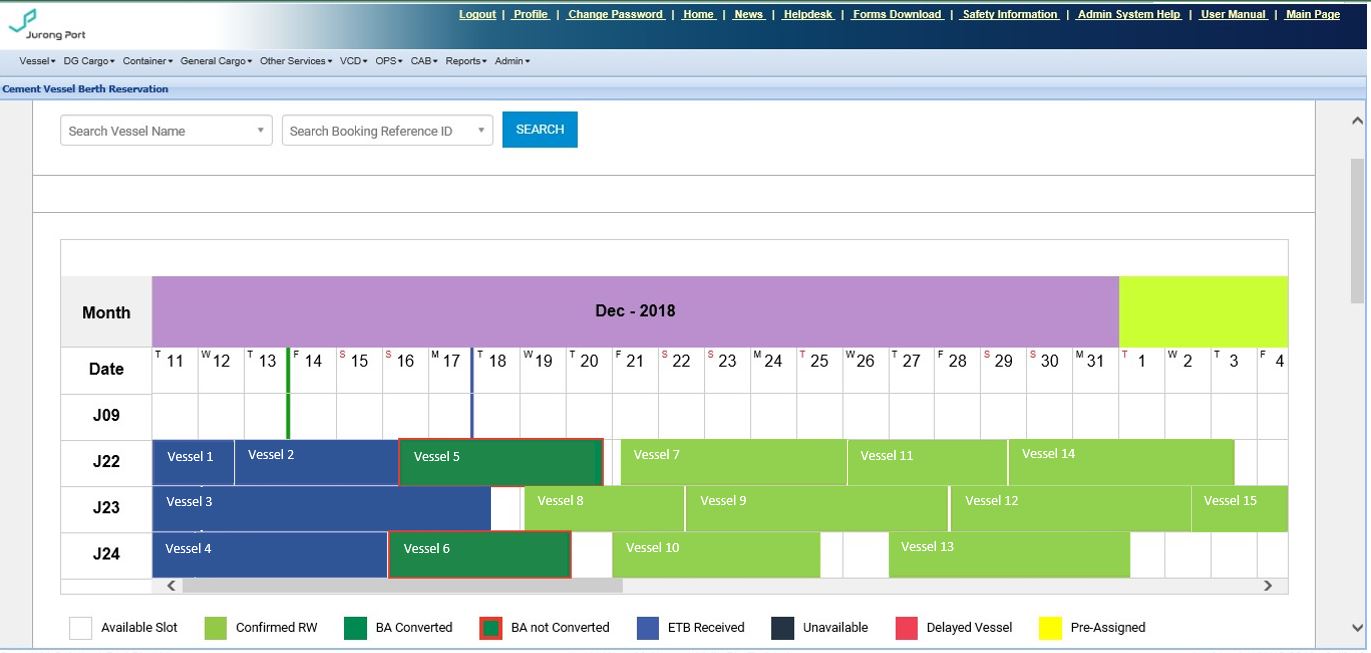

The Cement Vessel Reservation System (CVRS) is one of our more recent initiatives designed to achieve multiple objectives. They include the berth line-up visibility to the cement consignees for more efficient vessel schedule planning, reduced anchorage congestion and optimisation of cement terminal’s berth utilisation.

The design of a practical, usable and operational berth reservation system included extensive engagement with the Port’s incumbent cement consignees. It is a move away from the traditional First-come-First-serve (FCFS) approach employed port-wide to better address the unique dynamics of the cement terminal. The CVRS platform, while being its own system, seamlessly interfaces with the Port-wide berthing system software (JBPS). The CVRS launched in August 2017 and continues to evolve in response to user feedback.

A STEP TOWARDS REMOTE OPERATIONS

Leading cement companies call Jurong Port their home with their own custom-built silos and delivery systems. Efficient discharging operations and forward planning for berth usage ensure reliable handling of cement supplies to meet our customers’ requirements.

KEY STATISTICS

HAVE A BUSINESS ENQUIRY?

Call +65 6265 0666 or submit an enquiry, and our friendly customer service officer will be in touch with you as soon as possible.